Entwicklung & Produktion

We make

BOTTLES.

Mit innovativen und herausragend designten Verpackungslösungen

verschaffen wir unseren Kunden den entscheidenden Wettbewerbsvorteil

in einem eng umkämpften Markt.

Flaschenfinder

PET-Flasche finden & direkt online anfragen

Sie möchten für Ihr Produkt die passende Verpackung aus PET finden? Nutzen Sie unseren EPRO-FLASCHENFINDER und finden Sie schnell und übersichtlich genau die PET-Flasche, mit der Ihr Produkt am POS auffällt.

Mit Leichtigkeit wird aus einer PET-Flasche Ihre individuelle Verpackung.

Über uns

EPROPLAST – Wir sind ihr Spezialist für die Entwicklung und Produktion innovativer PET-Flaschen und deren Preforms. Aufgrund unserer eigene Preform-Fertigung sichern wir ihnen eine gleichbleibend hohe Qualität aller Verpackungslösungen.

We make bottles

Dabei bieten wir unseren Kunden eine individuelle und umfängliche Betreuung von der Designentwicklung, über den Formenbau, bis hin zur Erst- und Serienproduktion. Lassen sie sich von unserem one-stop shopping Service überzeugen.

recyceltes PET

Warum entscheiden wir uns für rPET? Nachhaltiges PET spielt eine entscheidende Rolle bei der Reduzierung unseres ökologischen Fußabdrucks. Es ermöglicht uns, wertvolle Ressourcen zu erhalten und den Kreislauf der Kunststoffproduktion zu schließen.

EPROPLAST bietet Ihnen eine breite Palette von PET-Flaschen mit einem Rezyklat-Anteil von 30 %, 50 % oder sogar 100 % an.

PET - Prozess & Verarbeitung

PET-Verpackungen überzeugen durch Brillanz & Transparenz

Hohe Transparenz und brillante Oberflächen verleihen PET-Verpackungen eine außergewöhnlich edle Optik. Neue Etikettierlösungen mit beidseitig bedruckten Etiketten geben ihrem Produkt die Aufmerksamkeit, die es am POS benötigt.

Unser flexibles Produktionsverfahren erlaubt eine nahezu unbegrenzte Designvielfalt. Im Besonderen das Maschinen- und Werkzeugkonzept von EPROPLAST erlaubt eine individuelle Formgestaltung mit minimalen Werkzeugkosten.

Ihr Vorteil - PET verpackt besonders leicht

Bis zu 90% Gewichtsersparnis gegenüber Glas! Dadurch wird nicht nur der Transport wirtschaftlicher, sondern auch umweltfreundlicher. Schließlich liegt all unseren Entwicklung das Design for Recycling als Ansatz zugrunde.

Aufgrund der besseren mechanischen Eigenschaften werden auch gegenüber PE- oder PP-Flaschen Gewichtseinsparungen erzielt. Im Vergleich zum Extrusionsblasformen fällt im PET-Produktionsprozess kein Materialabfall an.

Sicherheit als herausragende Eigenschaft von Kunststoff

Wegen der hervorragenden Materialeigenschaften sind PET-Flaschen nahezu unzerbrechlich. Dadurch entsteht bei der Abfüllung, dem Transport und dem Gebrauch kein Bruch. So lassen sich durch den Werkstoff PET langfristig Ressourcen sparen.

Selbst bei einer Beschädigung gibt es keine Splitterteile, die Verletzungen verursachen können. PET sorgt für den optimalen Schutz bei allen Verbrauchern.

Aktuelles & Neuigkeiten

Cosmetic Business 2024

Cosmetic Business in München – vom 5. – 6. Juni 2024 📅. Wir stellen aus! Sie finden uns wieder in...

Zum ArtikelBeautiful packaging

Auf der Suche nach einer Verpackung, die sich abhebt? Ganz gleich, ob Sie in der Lebensmittel-, Reinigungs- oder Kosmetikindustrie tätig...

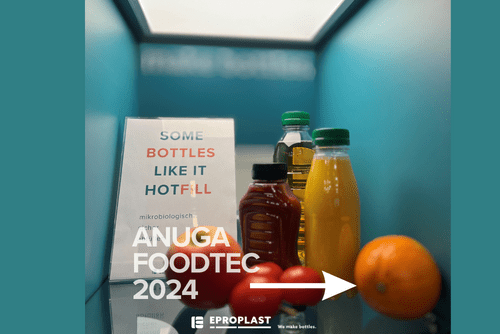

Zum ArtikelHeißabfüllung

Die Heißabfüllung in PET-Flaschen ist eine sichere und seit vielen Jahren bekannte Abfülltechnologie. Durch die Heißabfüllung können unter anderem Fruchtsäfte...

Zum Artikel